UV Monomer Market: Driving Growth in the Era of Green Chemistry

UV Monomer Market: Driving Growth in the Era of Green Chemistry

The global UV Monomer industry, a critical pillar of the radiation curing ecosystem, is entering a phase of accelerated transformation. With a projected market size of USD 3.5 billion by 2025 and an estimated compound annual growth rate (CAGR) of 4.6% through 2030, the sector is increasingly recognized as a strategic enabler of high-performance, environmentally friendly coatings, inks, and adhesives.

From Solvents to Sustainable Solutions

Unlike traditional solvent-based coatings and inks, which rely on volatile organic compounds (VOCs) and contribute significantly to air pollution, UV curing systems deploy reactive diluents—better known as UV monomers—that fully participate in the curing process. This not only reduces emissions but also allows for rapid film formation, low energy consumption, and superior coating properties.

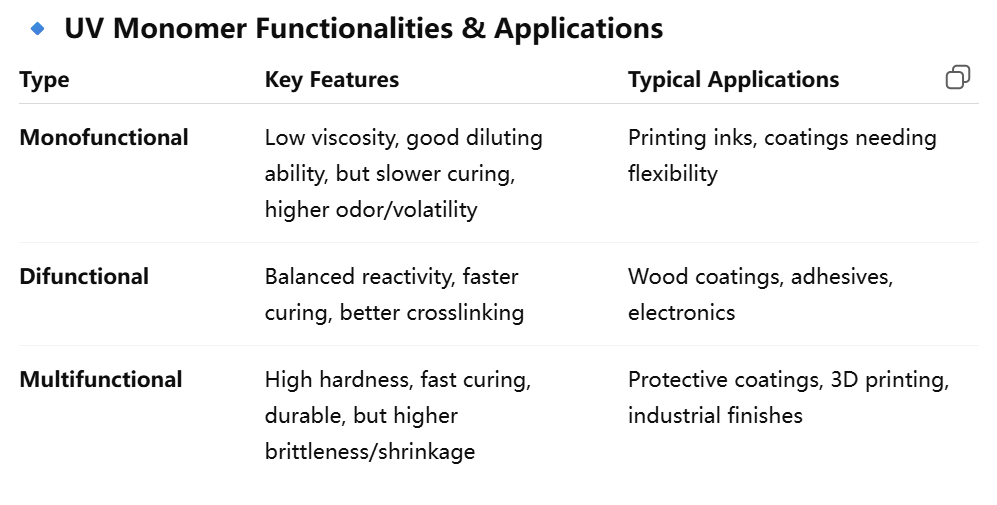

In the early stages of development, common monomers such as styrene and vinylpyrrolidone were widely used, though their high volatility, toxicity, and odor limited long-term adoption. Today, the market is dominated by acrylate-based monomers with varying functionalities—mono-, di-, and multi-functional—tailored to deliver the desired balance between viscosity, curing speed, hardness, and flexibility.

-

Monofunctional monomers provide low viscosity and excellent diluting power but suffer from slow curing and higher odor levels.

-

Difunctional monomers like HDDA and TPGDA strike a balance, offering fast curing, higher crosslinking density, and good diluting capacity.

-

Multifunctional monomers such as TMPTA, while more viscous, deliver rapid curing, superior hardness, and higher performance films, albeit with greater shrinkage and brittleness.

This functional diversity underpins the adaptability of UV monomers across industries, from wood coatings and packaging inks to optical fibers, electronics, and 3D printing resins.

Market Structure: Consolidation and Expansion

The UV Monomer market is marked by both consolidation among global leaders and expansion among regional challengers.

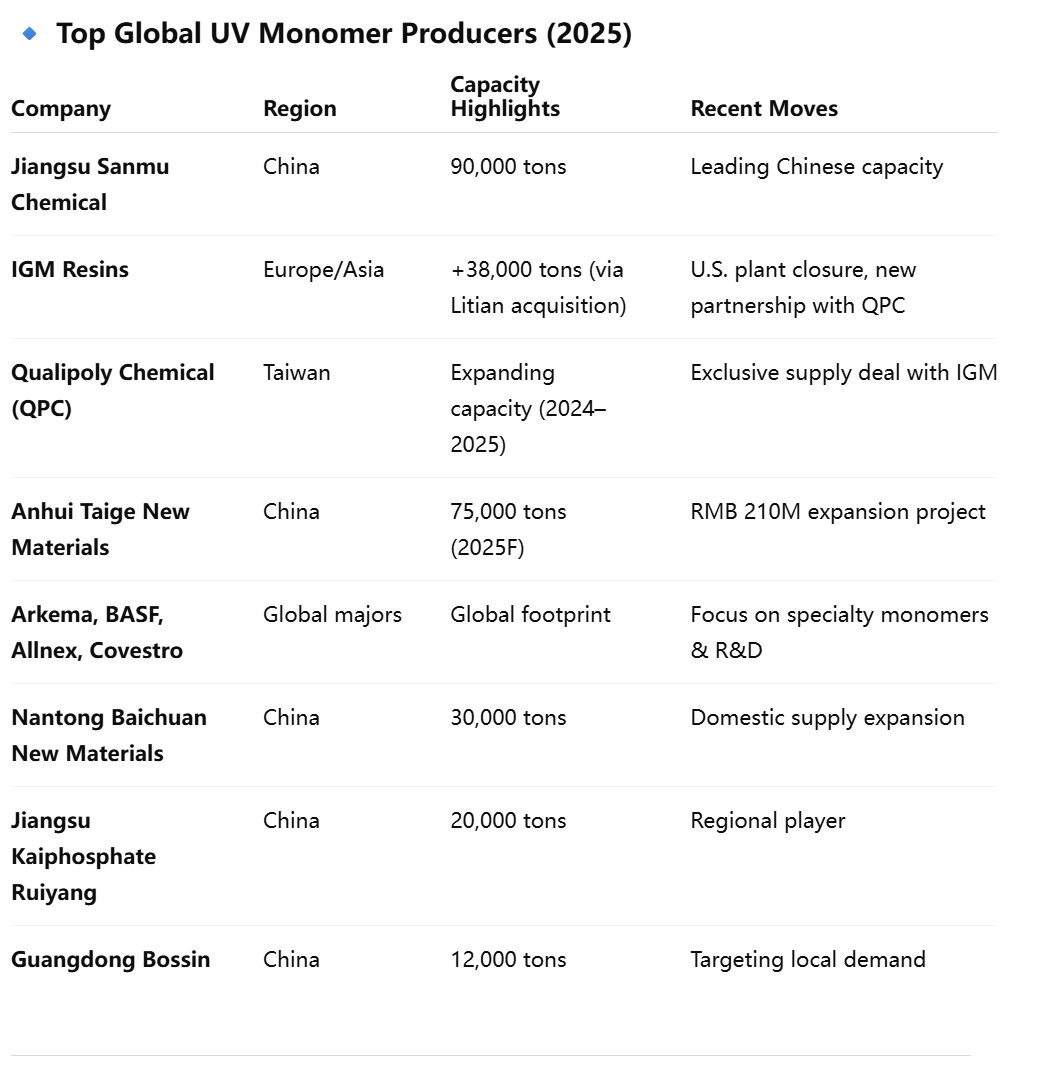

The top eight producers—Arkema, IGM Resins, Allnex, BASF, Covestro, Miwon Specialty Chemical, Eternal Materials, Qualipoly Chemical Corporation, and Jiangsu Sanmu Chemical—collectively shape the competitive landscape. Strategic maneuvers in recent years highlight the sector’s dynamism:

-

IGM Resins has both streamlined and expanded its portfolio, closing a U.S. monomer plant while acquiring Jiangsu Litian Technology in 2022, adding 38,000 tons of capacity. In February 2023, IGM also signed an exclusive supply and distribution agreement with Qualipoly Chemical Corporation, signaling a tighter integration of global supply chains.

-

Qualipoly Chemical Corporation is doubling down on capacity expansion, with significant investments planned through 2024 and 2025.

-

In China, Anhui Taige New Materials is investing RMB 210 million in a 60,000-ton UV monomer expansion project, with full commissioning expected in Q3 2025, bringing its total UV monomer capacity to 75,000 tons annually.

-

Other regional players, including Nantong Baichuan (30,000 tons), Jiangsu Kaiphosphate Ruiyang (20,000 tons), and Guangdong Bossin (12,000 tons), are contributing to an increasingly diversified supply base.

Such expansions are critical, as demand growth is expected to intensify amid tightening VOC regulations worldwide and surging adoption of eco-friendly curing technologies.

Growth Drivers: Regulation Meets Innovation

Several key forces are shaping the trajectory of the UV Monomer market:

- Environmental Regulations – Governments across the globe are imposing stringent restrictions on VOC emissions. Traditional solvent-based inks and coatings, which still account for nearly 60% of the global market, are under increasing pressure. UV-curable systems, nearly solvent-free by design, are emerging as the natural replacement.

- Technological Advancements – Progress in photoinitiator chemistry, LED curing systems, and hybrid monomer formulations is expanding the scope of UV curing applications, from flexible electronics to medical devices.

- End-Market Diversification – Beyond wood, paper, and plastics, UV monomers are finding applications in aerospace, automotive, solar photovoltaics, food packaging, and even dentistry. Their low-VOC, high-performance profile aligns with broader sustainability and performance requirements.

Challenges: Balancing Performance with Safety

Despite its robust growth prospects, the UV Monomer market faces formidable challenges.

-

Health and Safety Concerns: Certain monomers, particularly low-molecular-weight acrylates, are associated with skin irritation and odor issues. While industry trends favor higher-functionality, lower-volatility monomers, occupational exposure and regulatory scrutiny remain hurdles.

-

Raw Material Volatility: Dependence on petrochemical feedstocks exposes the market to price swings and supply chain vulnerabilities.

-

Performance Trade-offs: Multifunctional monomers deliver speed and hardness but also increase brittleness and shrinkage, complicating their use in applications requiring flexibility and adhesion.

Outlook: A Strategic Growth Frontier

The UV Monomer market’s evolution reflects the broader shift toward green chemistry and circular economy principles. By enabling rapid, solvent-free curing with minimal environmental footprint, UV monomers are positioned to capture significant share from solvent- and water-based technologies over the next decade.

For industry players, success will hinge on innovation in low-odor, bio-based monomers, strategic partnerships across the value chain, and capacity expansion in high-growth regions such as Asia-Pacific.

As one industry executive recently remarked, “UV curing is no longer a niche—it’s a mainstream technology. The monomers that underpin it are becoming indispensable to the global push for sustainable industrial solutions.”